Tungsten Carbide Stone Cutting Brazed Saw Tips

Of Good Wear And High Impact Resistance

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer's application.

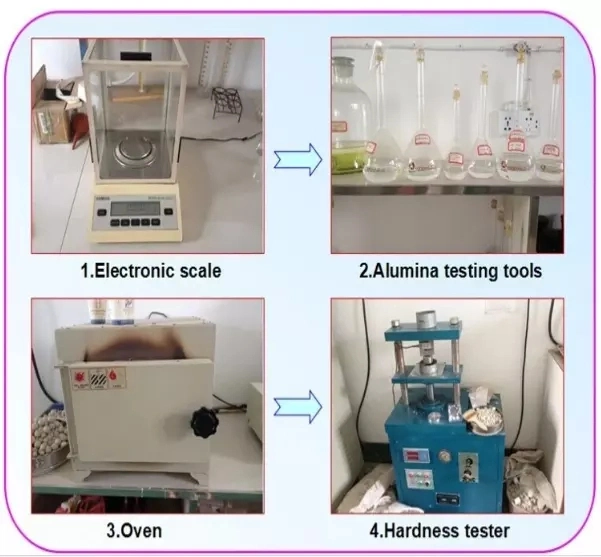

3. we have professional advanced production line and inspeciton equipments to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

Our saw tips include F series, US Standard and European Standard. All saw tips are HIP-Sintered, to make sure high quality, with automatic pressing to make sure accurate size, tumble and nickel covered to make sure good brazing performance.

Our brand has gain reputation from clients in Europe, USA, Asia, etc.

Our grades cover all ISO range, suitable to cut grass, hard wood, recycle wood, metal, plastic, PVC, MDF, Melamine board, plywood, etc.

| Grade | Application recommended |

| YG6/ K20 | For the cutting of ordinary wood, Recommend to use resistance welding,and the temperature should not be too high |

| YG8/K30 | For the cutting of the ordinary wood,also for the aluminum, Recommend to use resistance welding,and the temperature should not be too high |

| YK08/K40 | For the cutting of the recycling wood especially for some iron nails and stones in it, Recommend to use resistance welding,and the temperature should not be too high |

| JX5/K20 | For the cutting of the hard wood/recycling wood and aluminum, Recommend to use resistance welding,and the temperature should not be too high |

| YG6X/K10 | For the cutting of the wood specially, recommend to use the high frequency welding |

| YG8X/K10 | For the cutting of the wood and aluminum specially, Recommend to use the high frequency welding |

| K10S | For the cutting of the hard wood specially, Recommend to use the high frequency welding |

| K20S | For the cutting of the aluminum specially, Recommend to use the high frequency welding |

| K10UF | For the cutting of the plywood,board with middle to high density and the compound materials with aluminum and plasic, Use the high frequency welding |

| K20UF | For the cutting of the aluminum specially, Use the high frequency welding |

| K30UF | For the cutting of the stones specially, Use the high frequency welding |

| R06 | For the cutting of the plywood,density board and the sandwich board, Use the high frequency welding |

| R03 | For the cutting of the timber such as shaving board,laminated boar,density board and compound material etc, Use the high frequency welding |

| YC40 | For the cutting of the large cast materials, Recommend to use the high frequency welding |

| YC501 | For the cutting of the steel and the stainless steel, Recommend to use the high frequency welding |