Tungsten carbide saw blade tips for cutting

The cemented carbide welding tool is made of cemented carbide blades and ordinary structural steel knives by welding. It is made of dehydrated borax, copper, ferromanganese, glass powder and other solders. It is melted at high temperature to make alloy, high speed steel and cubic nitride. Boring, diamond, ceramic and other blades are bonded to the same type of shank to meet the requirements of machining operations. The most widely used welding blade is the cemented carbide welding blade. Because the hardness of the hard alloy is high, it can meet the requirements of most materials to be processed, and it is widely used compared with other materials.

Hard alloy welding inserts have high hardness (86 ~ 93HRA, equivalent to 69 ~ 81HRC); good thermal hardness (up to 900 ~ 1000 ° C, maintain 60HRC); good wear resistance. Carbide tools are 4 to 7 times faster than high-speed steel, and tool life is 5 to 80 times higher. The molds and gauges are manufactured. The life is 20 to 150 times higher than that of alloy tool steel. It can cut hard materials of about 50HRC, but hard. The alloy is brittle and cannot be cut. It is difficult to form a whole-tool with a complicated shape. Therefore, it is often made into blades of different shapes and is mounted on the body or the mold body by welding, bonding, mechanical clamping or the like.

Carbide Grades for tungsten carbide brazed tips

| ISO Code | Grade | Density g/cm³ | Hardness HRA | TRS Mpa | Applications recommended |

| P10 | YT05 | 12.6 | 92.5 | 1260 | It is suitable for finishing of steel and casting steel machining, high cutting speed, small feed rate and low depth is recommended. |

| YT15 | 11.3 | 91.0 | 1300 | It is suitable for semi-finishing of steel and casting steel machining, high cutting speed, medium feed rate is recommended. | |

| P20 | YC201 | 11.79 | 91.8 | 1400 | It is suitable for semi-finishing and light roughing machining of steel, casting steel and stainless steel. It is suitable grade for a wide application. |

| YT14 | 11.4 | 90.5 | 1400 | It is suitable for semi-finishing of steel and casting steel. | |

| YS25 | 13.0 | 90.5 | 1780 | It is used for milling machining of steel and casting steel. | |

| P30 | YT5 | 12.8 | 89.5 | 1570 | Suitable for the heavy duty rough turning of steel and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions. |

| K20 | YD201 | 14.89 | 91.0 | 1800 | It is suitable for roughing to finishing machining of heat-resistance alloy, Ti alloy, casting iron and aluminum alloy. |

| YG6 | 14.9 | 89.5 | 1670 | It is suitable for light roughing and semi-finishing of casting iron, nonferrous metal, heat-resistance alloy and Ti alloy. | |

| YG8 | 14.6 | 89 | 1840 | It is suitable for semi-finishing and roughing of casting iron, nonferrous metal, heat-resistance alloy and Ti alloy at continuous and intermittent machining conditions. | |

| M20 | YM201 | 13.9 | 93.0 | 1600 | It is suitable for semi-finishing of Fe, Ni high temperature alloy, cold hard cast irons, stainless steel with good heat-resistance and nonferrous metal. It is a wide application |

| YS2T | 14.4 | 91.5 | 1960 | It is suitable for finishing and semi-finishing of stainless steel, alloy steel, Fe alloy. | |

| YW2 | 12.9 | 90.5 | 1460 | It is suitable for semi-finishing and light roughing of stainless steel and alloy steel. |

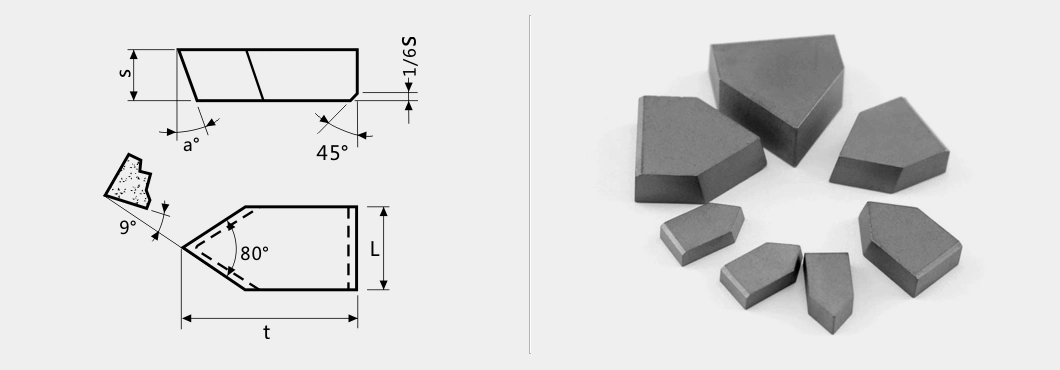

Type E2

| Type | Dimensions(mm) | |||

| L | t | S | a° | |

| E4 | 4 | 10 | 2.5 | - |

| E5 | 5 | 12 | 3 | - |

| E6 | 6 | 14 | 3.5 | 9 |

| E8 | 8 | 16 | 4 | 9 |

| E10 | 10 | 18 | 5 | 9 |

| E12 | 12 | 20 | 6 | 9 |

| E16 | 16 | 22 | 7 | 9 |

| E20 | 20 | 25 | 8 | 9 |

| E25 | 25 | 28 | 9 | 9 |

| E32 | 32 | 32 | 10 | 9 |

*We can offer this type in other grade and different dimension.

Tungsten Carbide Brazed Tips is a composite material composed of refractory metal compound (hard phase) and bonded metal (bond phase) produced by powder metallurgy